1. Application scope

The IEC60695-5-11 specifies a needle test to simulate the effect a small flame which may result from fault conditions, in order to assess by a simulation technique the fire hazard. It is applicable to electro-technical equipment, its sub-assemblies and components and solid electrical insulating materials or other combustible materials.

2. Description of the test apparatus

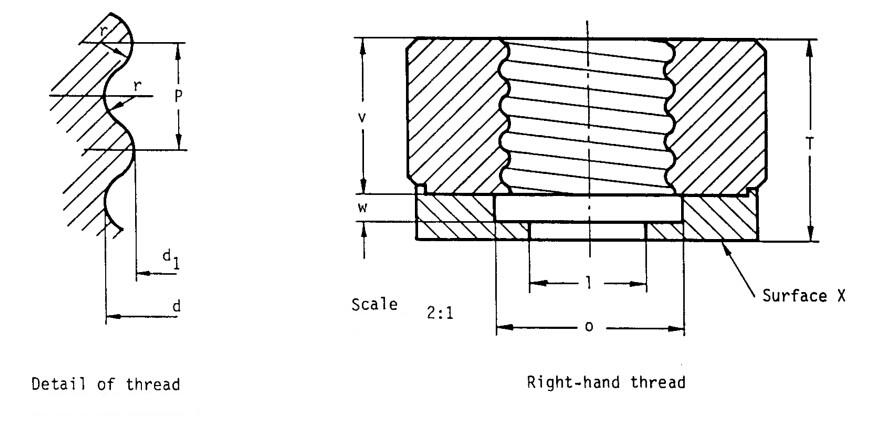

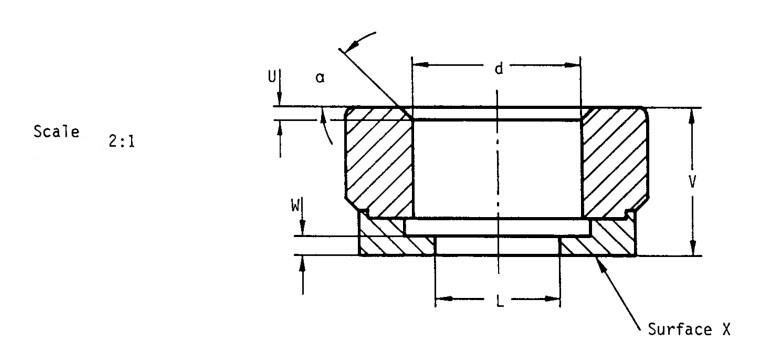

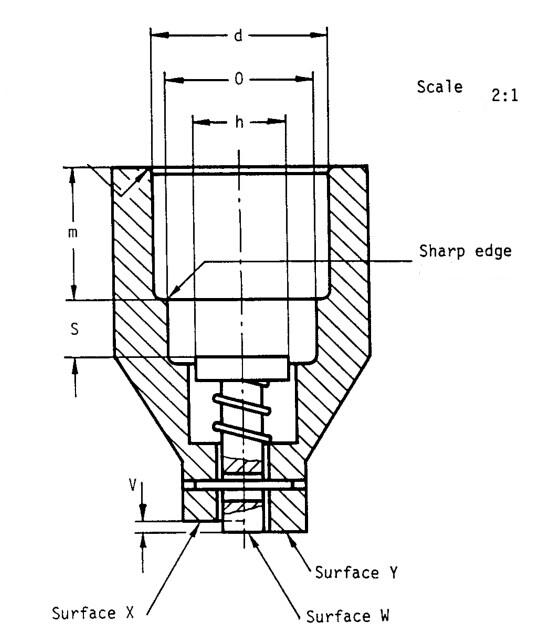

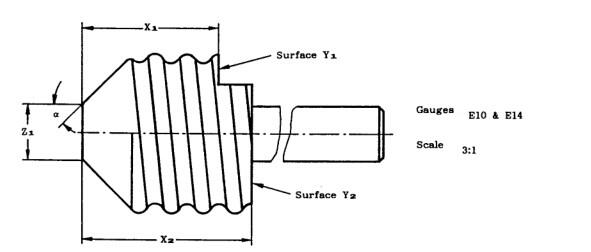

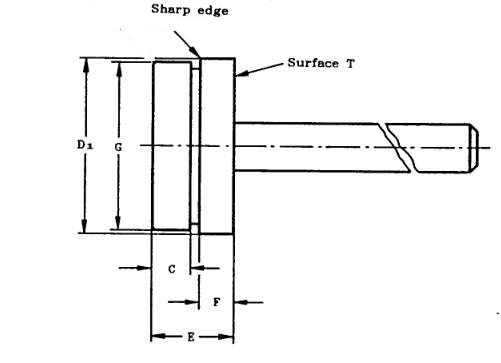

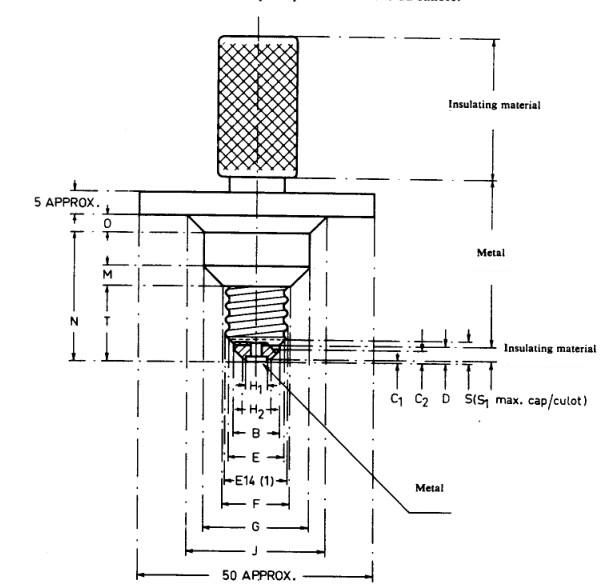

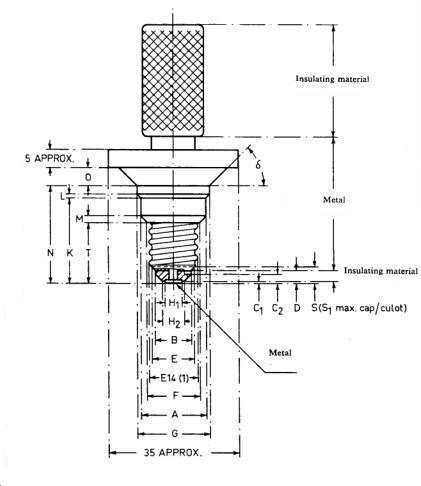

1) Burner: the burner to produce the test flame shall consist of a tub at least 35mm long with a bore of 0.5mm±0.1mm and an outer diameter not exceeding 0.9mm.The burner is supplied with butane or propane gas having gas having a purity of at least 95%.

ZY-2: The burner is made by stainless steel, the size is Φ 0.5mm ± 0.1mm, outer dia.: ≤Φ 0.9mm, Length: 35mm.

2) Flame: With the axis of the burner in the vertical position, the gas supply is adjusted so that the length of the flame is 12mm±1mm, when viewed in subbdued light against a dark background. The test time for the temperature to increase from 100℃±5℃ to 700℃±3℃ shall be 23.5s±1.0s.

ZY-2: The burner angle can be adjusted at 450 or 900. The flame height is 12mm ± 1mm (with height gauge), the background is black, the flame requirement is rising time from 100℃±2℃ to 700℃±3℃ should within 23.5s±1s.

3) Lab chamber: the lab chamber shall have an inside volume of at least 0.5m3. The chamber shall provide a draught-free environment, whilst allowing normal thermal circulation of air pass the test specimen. The chamber shall permit observation of the test in progress. The inside surfaces of the wall shall be a dark color.

ZY-2: The working dimension is 0.5CBM and made by stainless steel. The equipment with a view-window made by stalinite.

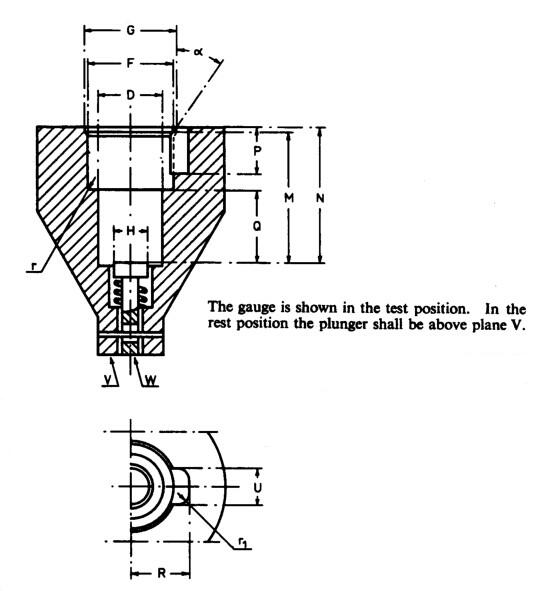

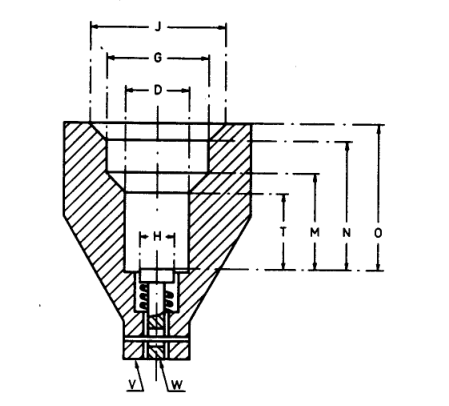

4) Thermocouple

A sheathed fine wire type K (NiCr/NiAl) with an outer sheath diameter of 0.5mm.

ZY-2: Thermocouple: Φ0.5mm K type

5) Severities

Preferred values of duration of application of test flame are as following:

5s, 10s, 20s, 30s, 60s, 120s

ZY-2:Burning duration: 0-999.9s±0.1s auto record, manual pause

4. Evaluation of test results

The test specimen is considered to have satisfactorily withstood the needle flame test if one of the following situation applies:

a. There is no flame and no glowing of the test specimen and no ignition of the specified layer or wrapping tissue.

b. Flames or glowing of the test specimen and surrounding parts extinguish within 30s after the removal of the needle flame. Also the surrounding parts have not burnt away completely and there has been no ignition of the specified layer or wrapping tissue.

See from the comparison, ZY-2 needle flame test apparatus completely meets the requirement of IEC60695-5-11. Meanwhile, Pego provides the third-Lab Calibration Certificate authorized by CNAS. Welcome to contact us to get more information.