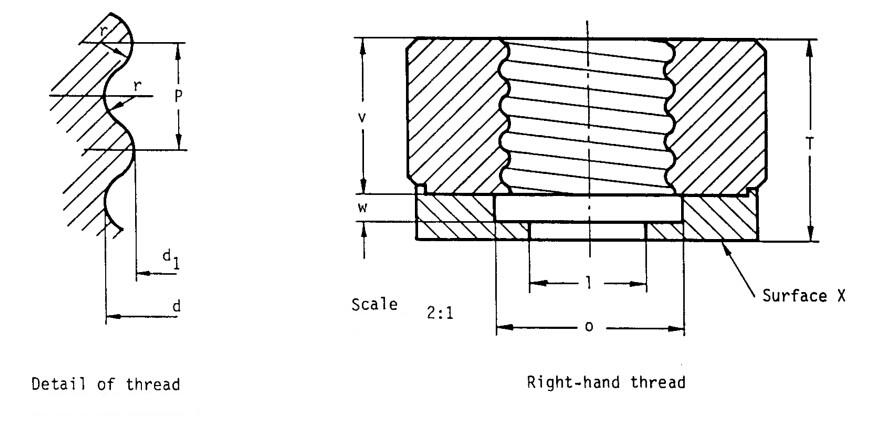

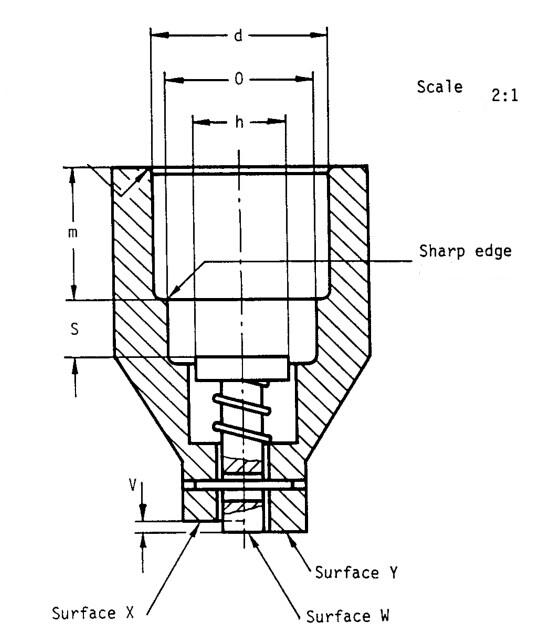

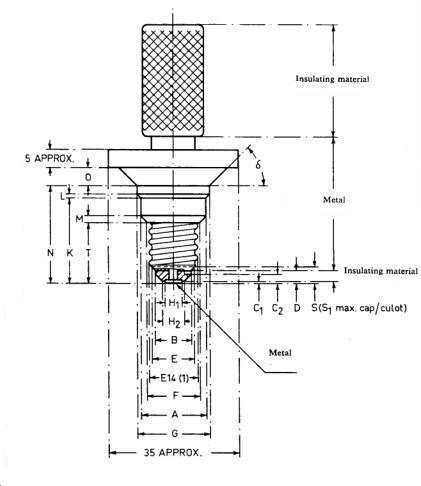

1) Go Gauge for E14 caps on finished lamps (7006-27F-1)

Purpose: To check the maximum dimensions of the screw thread and dimension T1 minimum of E14 caps on finished lamps.

Testing: when the cap on a finished lamp has been screwed into gauge as far as it will go, the centre contact shall be co-planar with, or project beyond surface X.

7006-27F-1

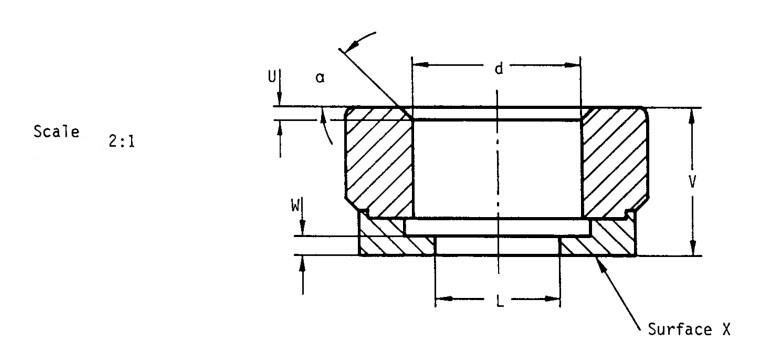

2) Not go gauge for E14 caps on finished lamps (7006-28B-1)

Purpose: to check the minimum outside(major) diameter of the screw thread, dimension d, of E14 caps on finished lamps.

Testing: when the gauge is placed over the thread of the cap on a finished lamp, held cap uppermost, the centre contact shall not project beyond surface X.

7006-28B-1

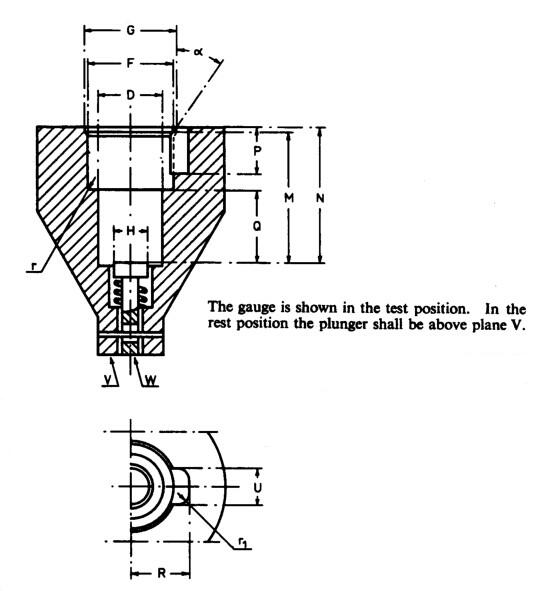

3) Gauge for finished lamps fitted with E14 caps for testing protection against accidental contact (7006-55-2)

Purpose: to check protection against accidental contact

Testing: The shape of the lamp with regard to protection against accidental contact is assumed to be correct if the test sample being pushed as far as possible into the gauge, plane W does not protrude beyond plane V.

Note: The application of this gauge is restricted to the lamps (candle lamps, round bulb lamps, domestic tubular lamps, pygmy lamps) when they are fitted with E14 caps, in according with sheet 7004-23.

7006-55-2

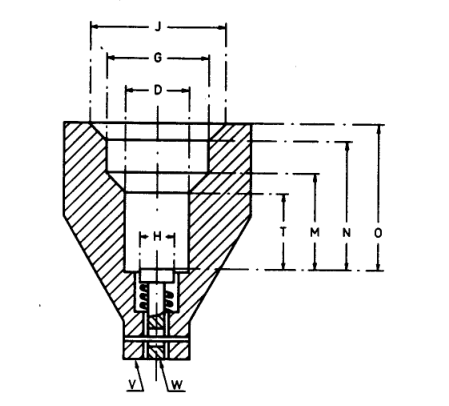

4) Gauge for finished lamps fitted with E14 caps for testing contact making (7006-54-2)

Purpose: to check lamp dimension for contact making in IEC holders

Testing: the shape of the lamp with regard to the fit in the lampholder is assumed to be correct if the lamp can be pushed into the gauge till plane W reaches plane V or projects beyond it.

5) Go gauge for dimension “S1” of E14 caps on finished lamps (7006-27G-1)

Purpose: To check the dimensions S1 minimum and S1 maximum of E14 caps on finished lamps.

Testing: When the cap on a finished lamp has been pushed into the gauge as far as it will go, the plunger surface W shall be co-planar with or project beyond surface X but it shall not project beyond surface Y.

7006-27G-1

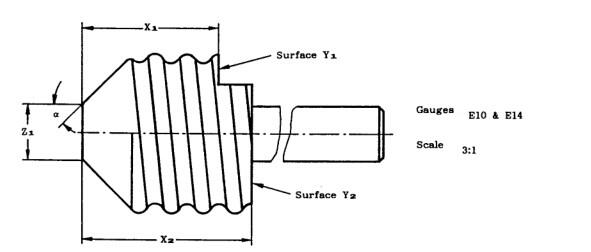

6) Go gauges for screw threads of E14 lampholders (7006-25-7)

Purpose: to check the minimum dimensions of the lampholder screw thread and dimension X shown on sheet 7005-20

Testing: it shall be possible to screw the gauge into the lampholder without using undue force.

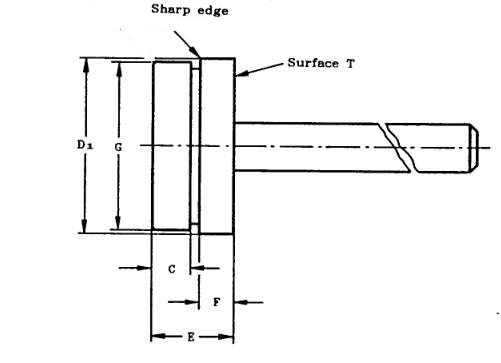

7) Not go gauges for screw threads of E14 lamp holders (7006-26-4)

Purpose: to check the maximum minor diameter of the screw thread, dimension D2 of lampholder E14.

Testing: the screw thread of the lampholder shall be assumed to be correct if the gauge does not enter by its own weight so far that the thread protrudes beyond surface T.

7006-26-4

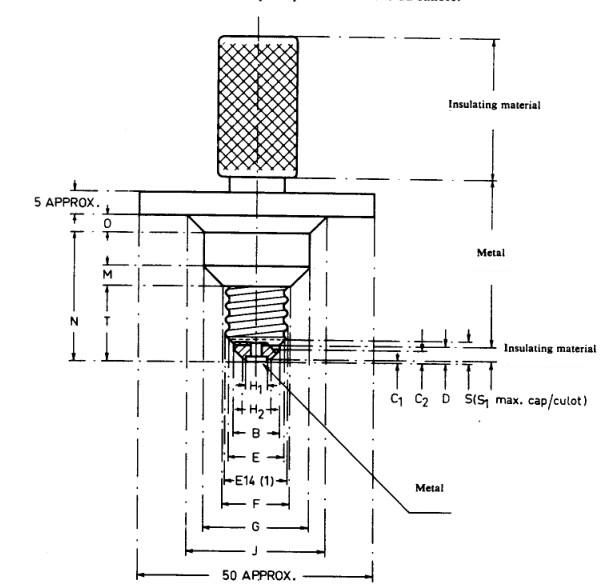

8) Plug gauge for E14 lampholder for testing contact making ( 7006-30-2)

Note: the application of this gauge is restricted to lampholders for lighting fittings equipped with the lamps (candle lamps, round bulb lamps, domestic tubular lamps, pygmy lamps) when these are fitted with E14 caps, in accordance with sheet 7004-23

9) Plug gauge for lampholder E14 with candle sharped shaft for candle lamps for testing contact making (7006-30A-1)

This gauge is to be used for testing contact making in lampholders with candle sharped shafts designed especially to make candle lamps only.

7006-30A-1

10) Guage for testing contact-making and protection against accidental contact during insertion of lamps E14 lampholder (figure number: 7006-31-4)

Note: the application of this gauge is restricted to lampholders for lighting fitting equipped with lamps (candle lamps, round bulb lamps, tubular lamps, pygmy lamps) when these are fitted with E14 caps, in accordance with sheet 7004-23

没有评论:

发表评论